info@vibrocut.de

info@vibrocut.de

Turning is of great importance as the primary process for manufacturing rotationally symmetrical components. With VIBROturn, chip breaking is improved during turning, thereby increasing productivity and process reliability.

In turning, the chip breaking problem has not yet been solved reliably. When machining materials with ductile material behavior, this leads to the formation of long helical and tangled chips. Insufficient chip breaking causes process uncertainties along the chip flow – this results in damaged surfaces, tool breakage (1) and clamping errors (2). In addition, chip packings form in the work area, causing a risk of collision (3) and restricting removal from the lathe by chip conveyors and thus automation (4). As a result, process stops for manual chip removal are necessary, which reduce machine availability and lead to a risk of injury for the machine operator. In addition, the low chip volume results in additional effort during transportation (5). The result is inefficient chip processing (6).

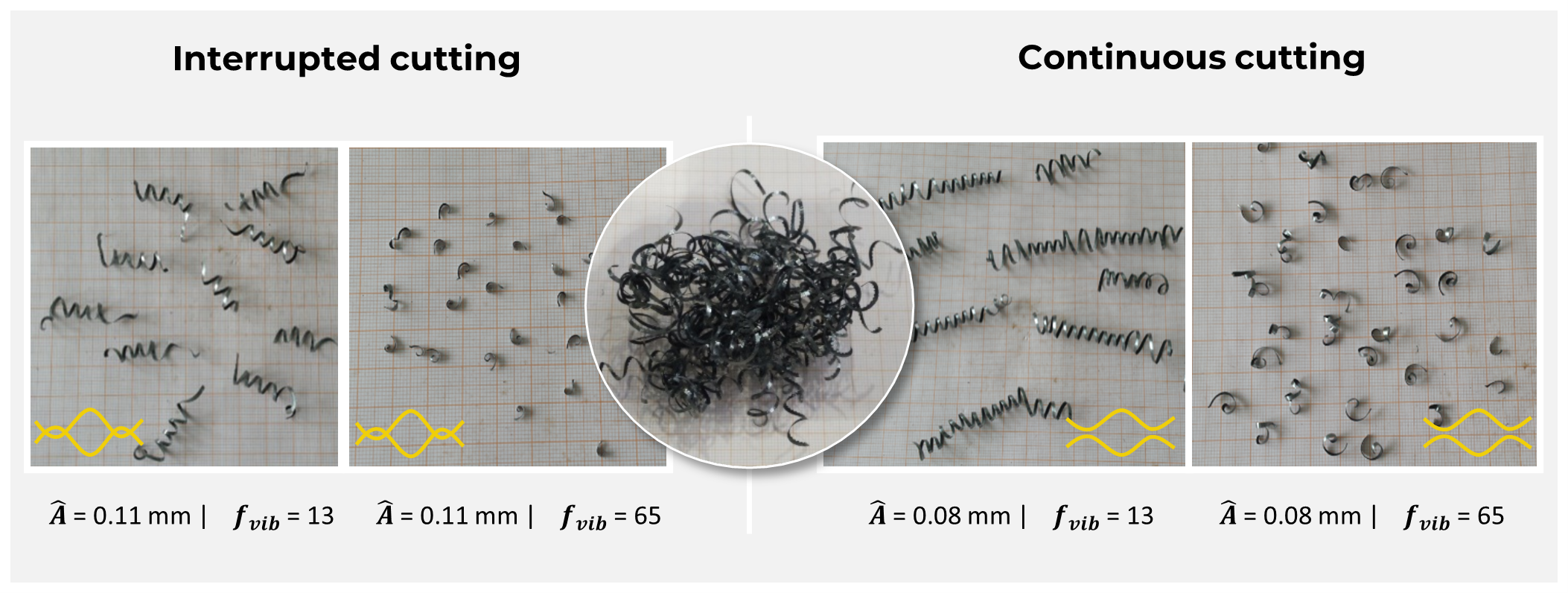

By using the VIBROturn tool holder, chip formation can be specifically adjusted. If the vibration amplitude is greater than the feed rate, interruptions of the cut occur which directly lead to an interruption in chip formation and therefore to short broken chips.

Improved chip breaking behavior is also achieved if no interruptions of the cut are generated. The thickness of the chip is changed periodically to create predetermined breaking points in the chip.

The advantage for the user is a stable and economical chip breaking behavior, with a high robustness against influencing variables such as tool wear or batch variations. Process reliability and machine availability during turning increase significantly. Since the conventional turning process is superimposed, the vibration assistance is cycle time neutral. Another essential advantage of VIRBOturn is the increase in process reliability. In many applications, automation of the production process is not possible due to problematic chip breaking. By safely breaking chips, VIBROturn enables automated and unmanned operation of the lathe.