info@vibrocut.de

info@vibrocut.de

![]()

The superimposition of additional movements in manufacturing processes, especially machining processes, is an innovative approach to improving performance and shifting existing physical limits.

An additional movement is superimposed onto the conventional process as oscillation in the low-frequency range or as ultrasound. The use of these technologies in industrial machining processes offers a wide range of advantages.

We at VibroCut GmbH are pioneers in hybrid machining and offer complete solutions for your production to increase productivity, process reliability, quality and cost-effectiveness.

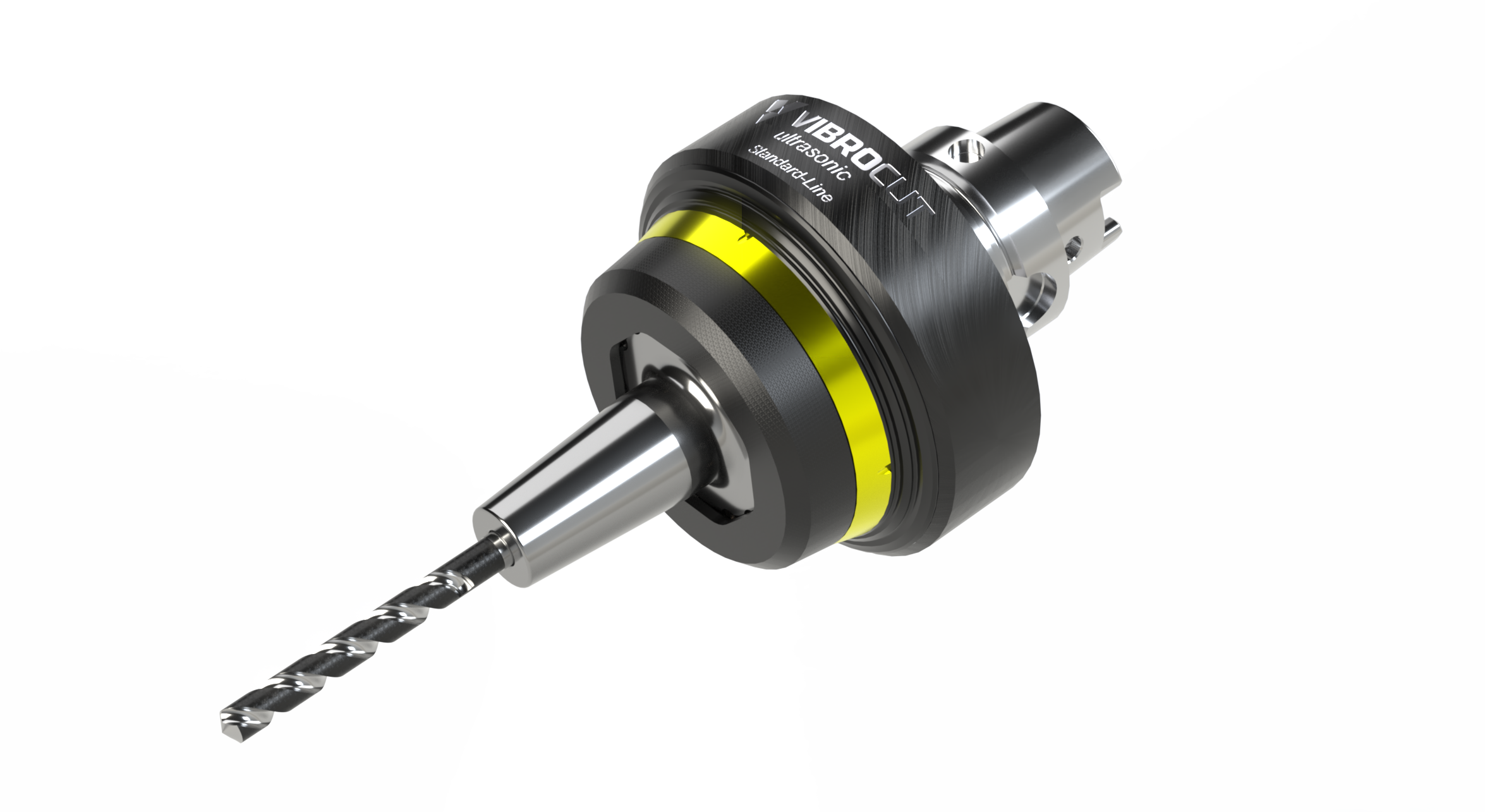

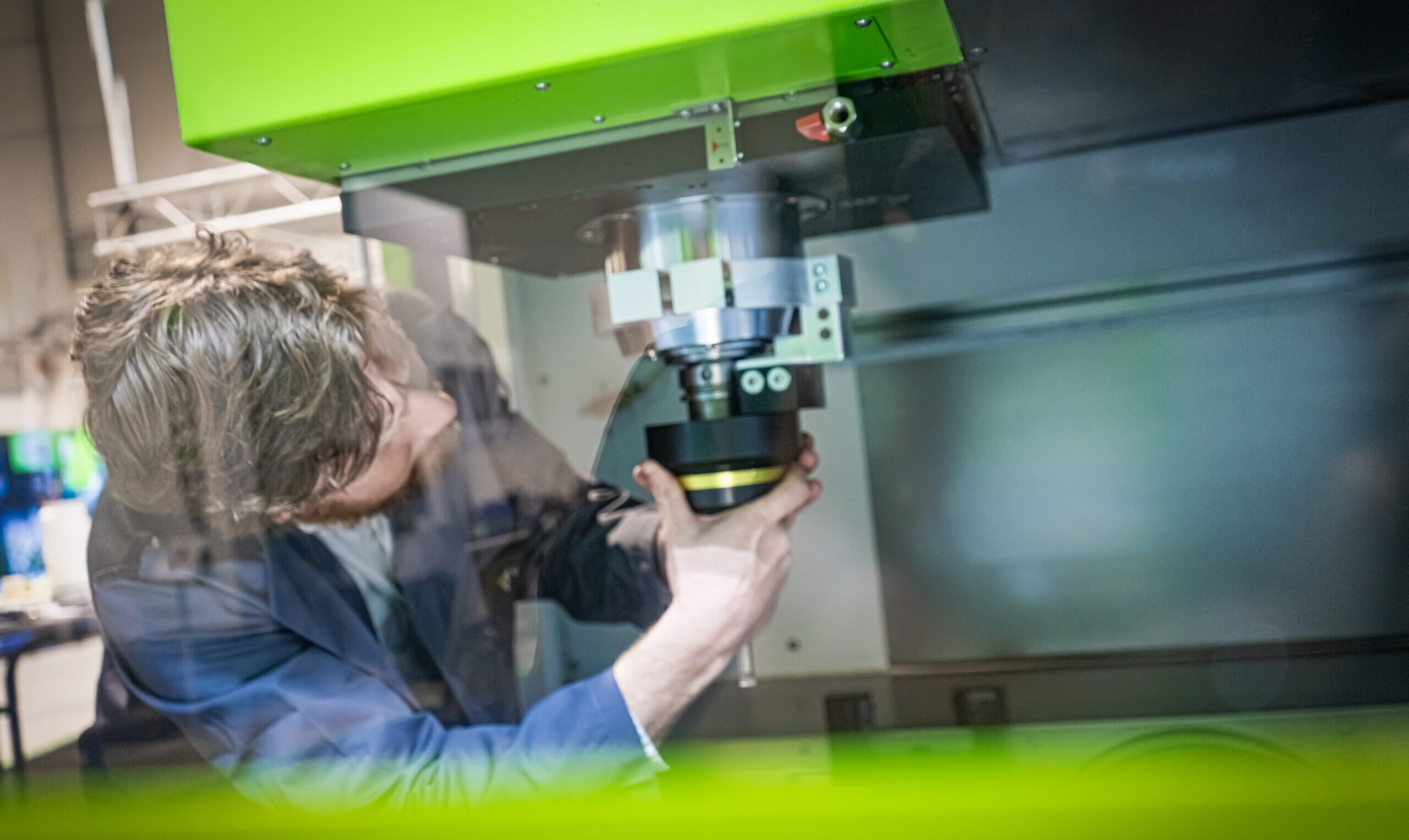

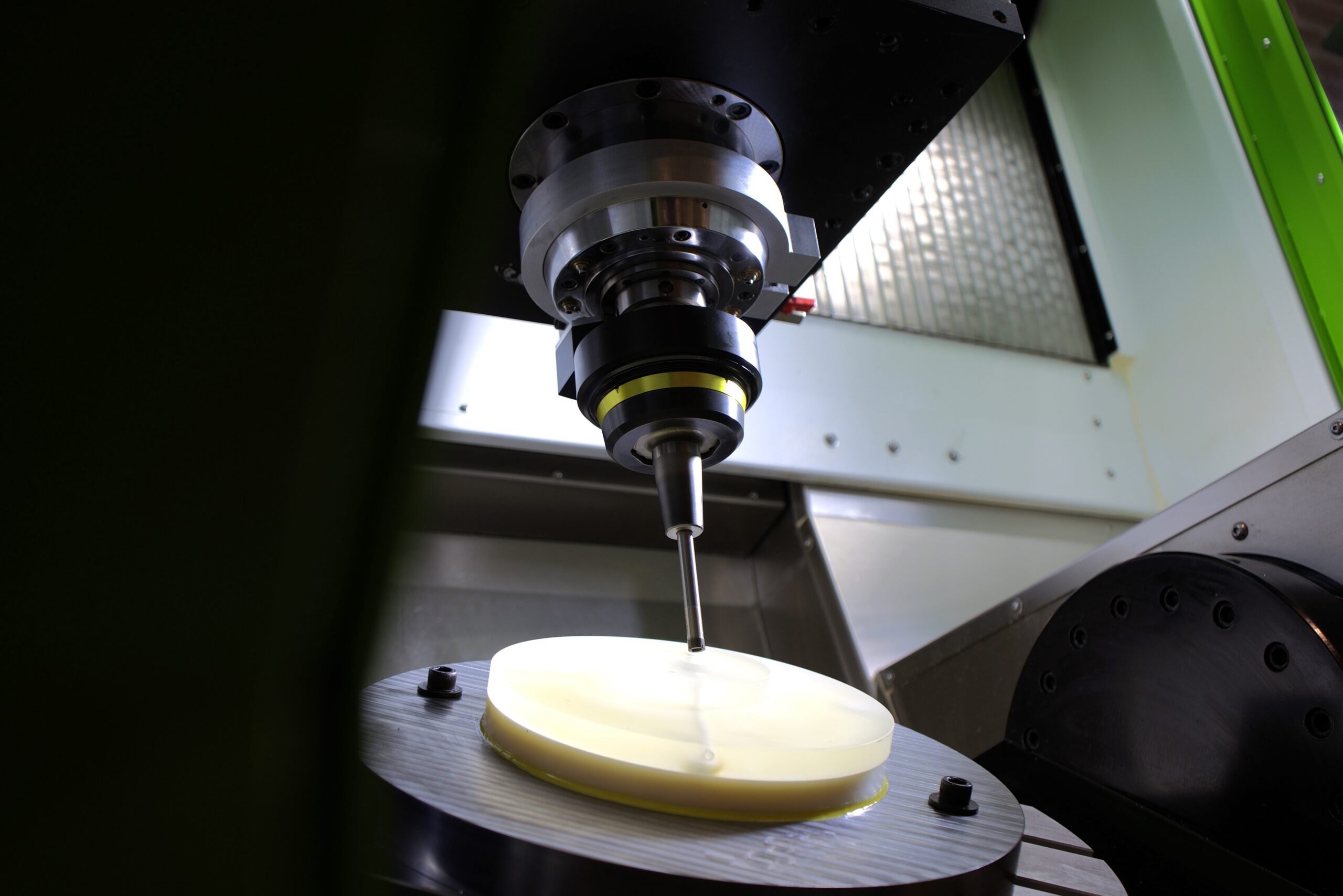

Discover the innovative technology of VibroCut ultrasonic, our ultrasonic systems for industrial production. The tool holders generate high-frequency ultrasound and thus optimize the cutting process. Manufacturing companies benefit from increased productivity, process reliability, quality and cost-effectiveness.

Learn more about ultrasonic machining with VibroCut ultrasonic!

Ultrasonic systems

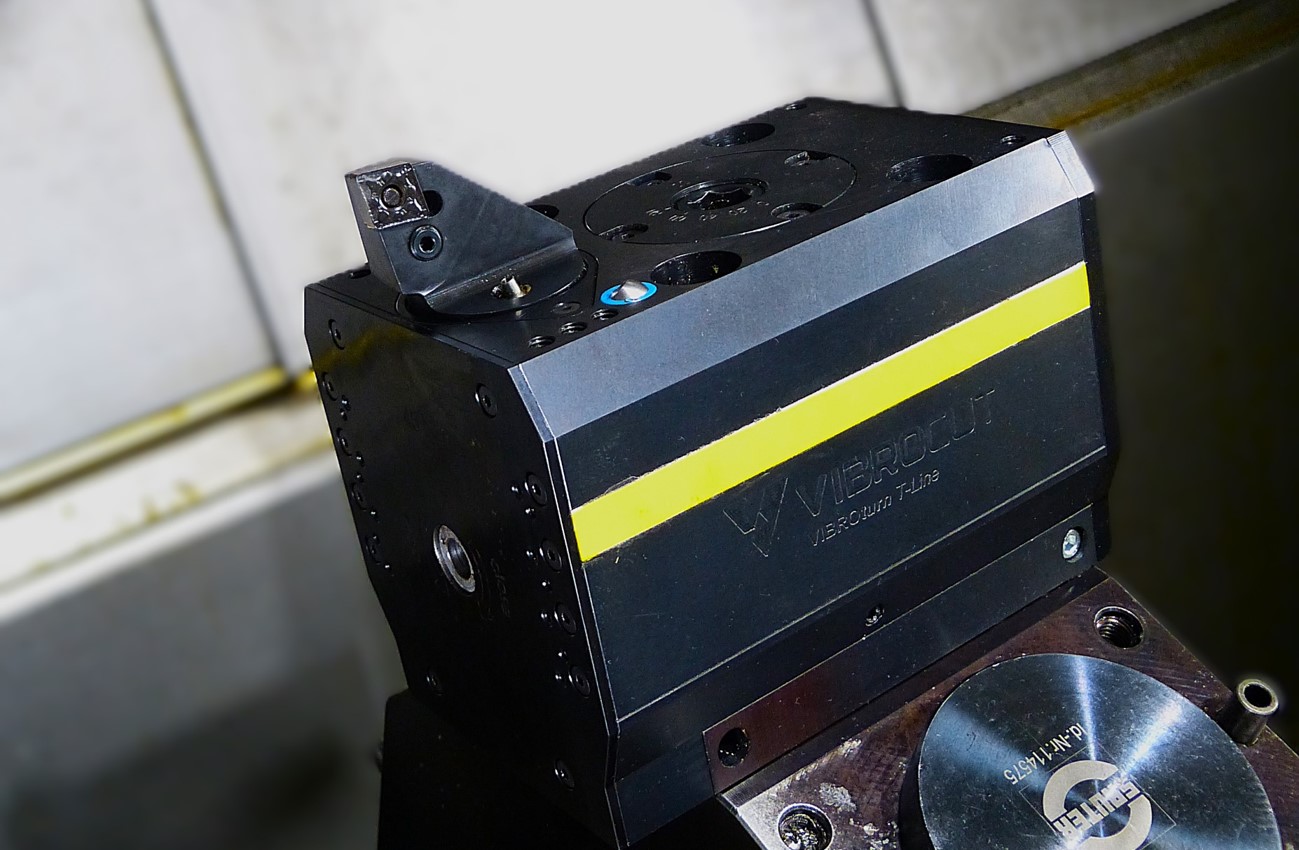

Discover the advantages of VibroCut oscillate, our oscillation system for machining. Our innovative tool holders enable reliable and economical chip breaking. With VibroCut oscillate, production interruptions are avoided, resulting in a significant increase in productivity.

Learn more about vibration-assisted machining with VibroCut oscillate!

Oscillation systemsWith VibroCut, you have a reliable partner at your side who offers you a complete solution for optimized machining. We supply innovative tool holders as retrofittable systems for your equipment and provide support in the areas of machining, technology development, machine integration, training, maintenance and service. From the development of customized technologies to the provision of custom-fit products and seamless integration into existing systems to the training of your team for optimal use – VibroCut is your full-service provider.

Services

Find out more about the application and your benefits when using VibroCut oscillate for turning. From face or longitudinal turning to grooving processes, this product guarantees short chips for improved machine availability and process reliability in your mechanical production.

Turning

Find out more about the application and your benefits when using VibroCut ultrasonic for drilling and deep hole drilling. From the use of delicate drilling tools to deep hole drilling operations – our technology increases productivity in drilling processes or enables the machining of difficult-to-cut materials.

Drilling & deep hole drilling

Find out more about the application and your benefits when using VibroCut ultrasonic for grinding brittle-hard materials. From fine grinding of sensitive components to processing brittle-hard materials – our technology improves process reliability and increases efficiency in demanding grinding operations.

Grinding