info@vibrocut.de

info@vibrocut.de

Get an overview of the versions of our ultrasonic systems including technical data and spindle interfaces.

Download now

All basic information on our systems for ultrasonic-assisted drilling and deep hole drilling at a glance.

Download now

Get a comprehensive insight into the diverse applications of our ultrasonic systems.

Download now

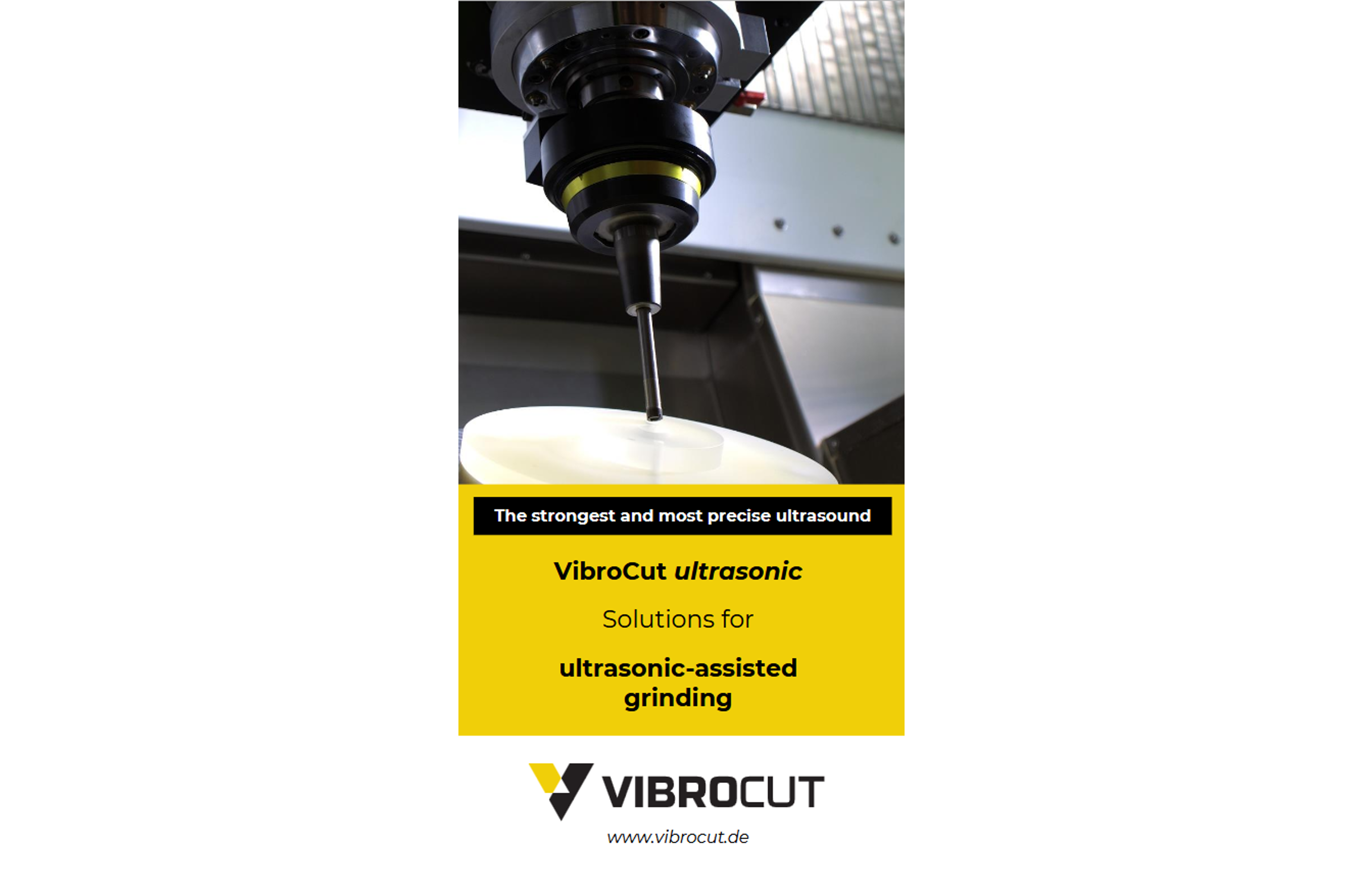

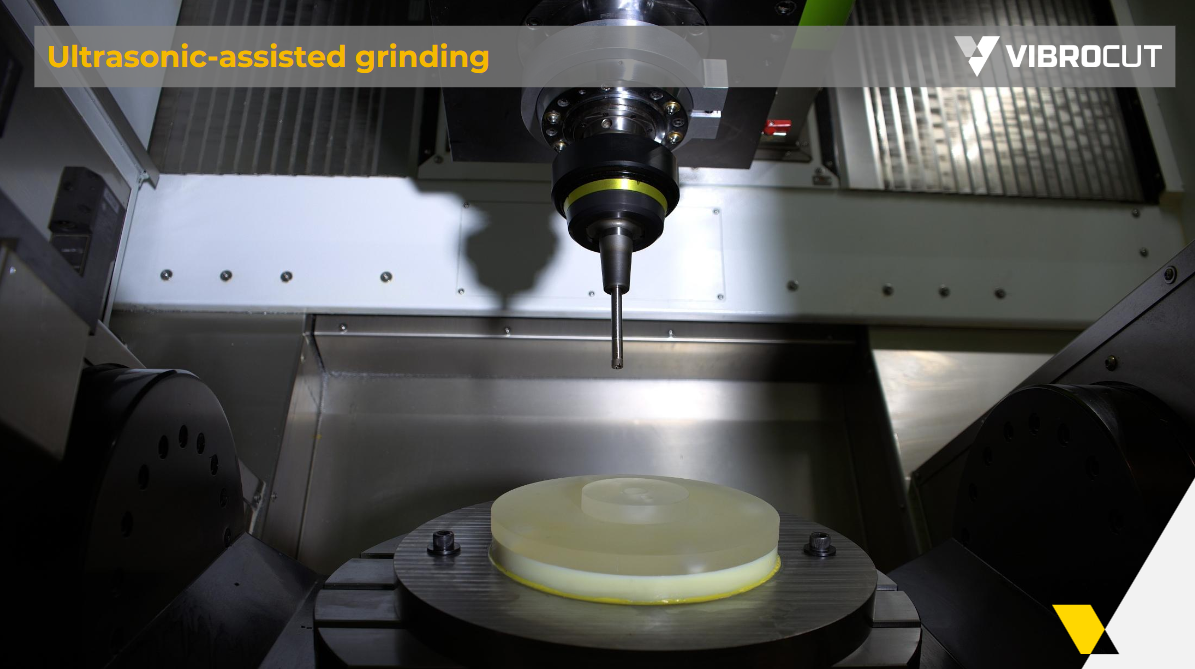

All basic information on our systems for ultrasonic-assisted grinding at a glance.

Download now

Get a comprehensive insight into the diverse applications of our ultrasonic systems.

Download now

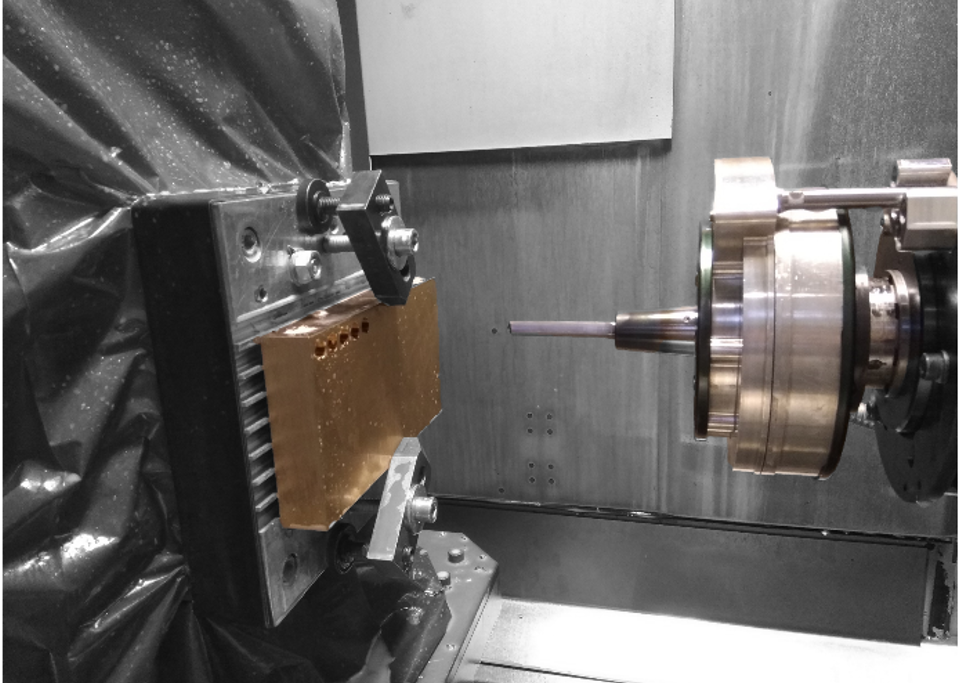

Despite their comparatively low strength, copper-based materials and low-alloy copper alloys in particular are considered difficult to machine. The reason for this is the tough material behavior with high formability. This results in poor chip formation behavior and high machining forces, which pose a challenge for industrial processes in terms of productivity, process reliability and quality.

Download now

Aluminum alloys are used as wrought or die castings in many industries. Their favorable material properties and good machinability make them ideal for high-volume series production. The focus is on optimizing productivity, quality and process reliability. Ultrasonic-assisted drilling and deep drilling processes reduce cutting forces and friction, which significantly increases the efficiency of machining aluminum alloys.

Download now

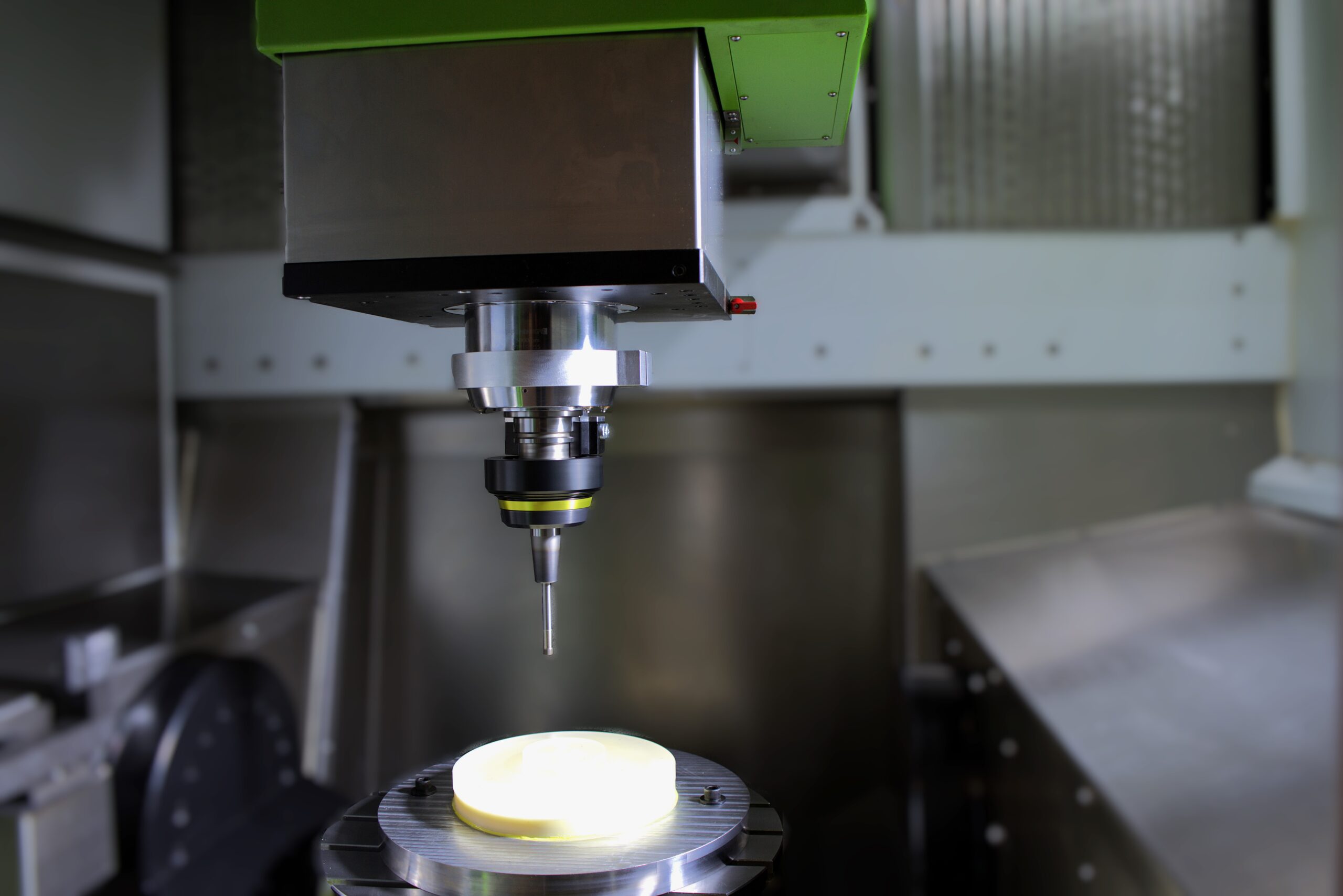

Quartz glass and aluminum oxide are essential materials in high-tech industries, but place high demands on machining due to their hardness and brittleness. Ultrasonic assistance in the grinding processes reduces process forces, improves surface quality and minimizes tool wear. With VibroCut ultrasonic, even complex geometries can be machined precisely and efficiently.

Download now

All basic information about our oscillation systems at a glance.

Download now

Get an overview of the versions of our oscillation systems including technical data and machine interfaces.

Download now

Get an insight into the technology of our oscillation systems.

Download now

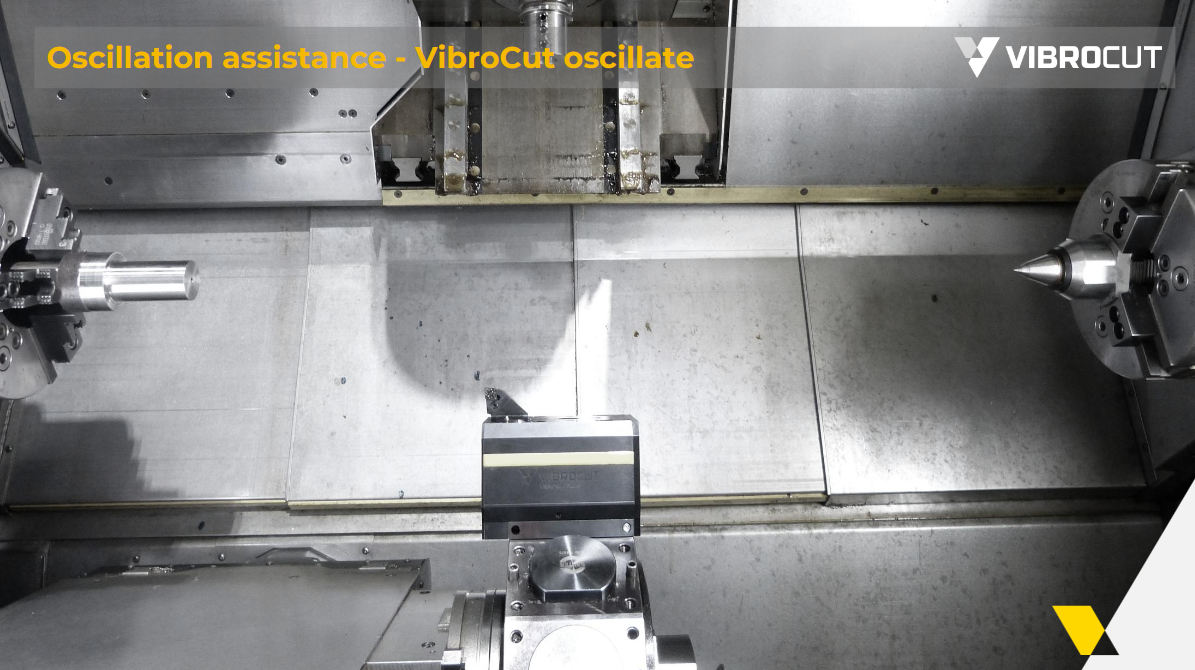

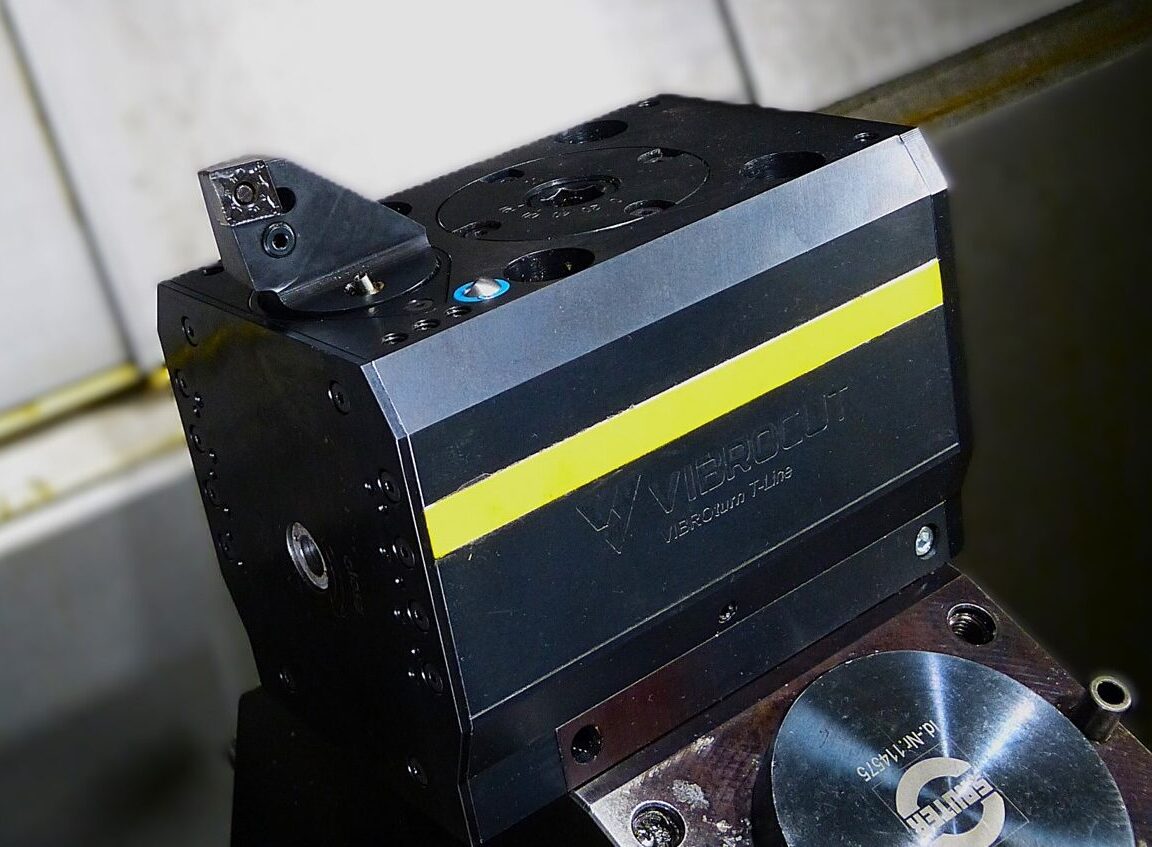

Oscillation support for the turning process is an innovative method for solving the chip breaking problem. With the help of the VibroCut oscillate system, chip formation can be specifically adjusted. If the oscillation amplitude is greater than the feed rate, cutting interruptions occur which directly lead to an interruption in chip formation and therefore to short broken chips.

Download now

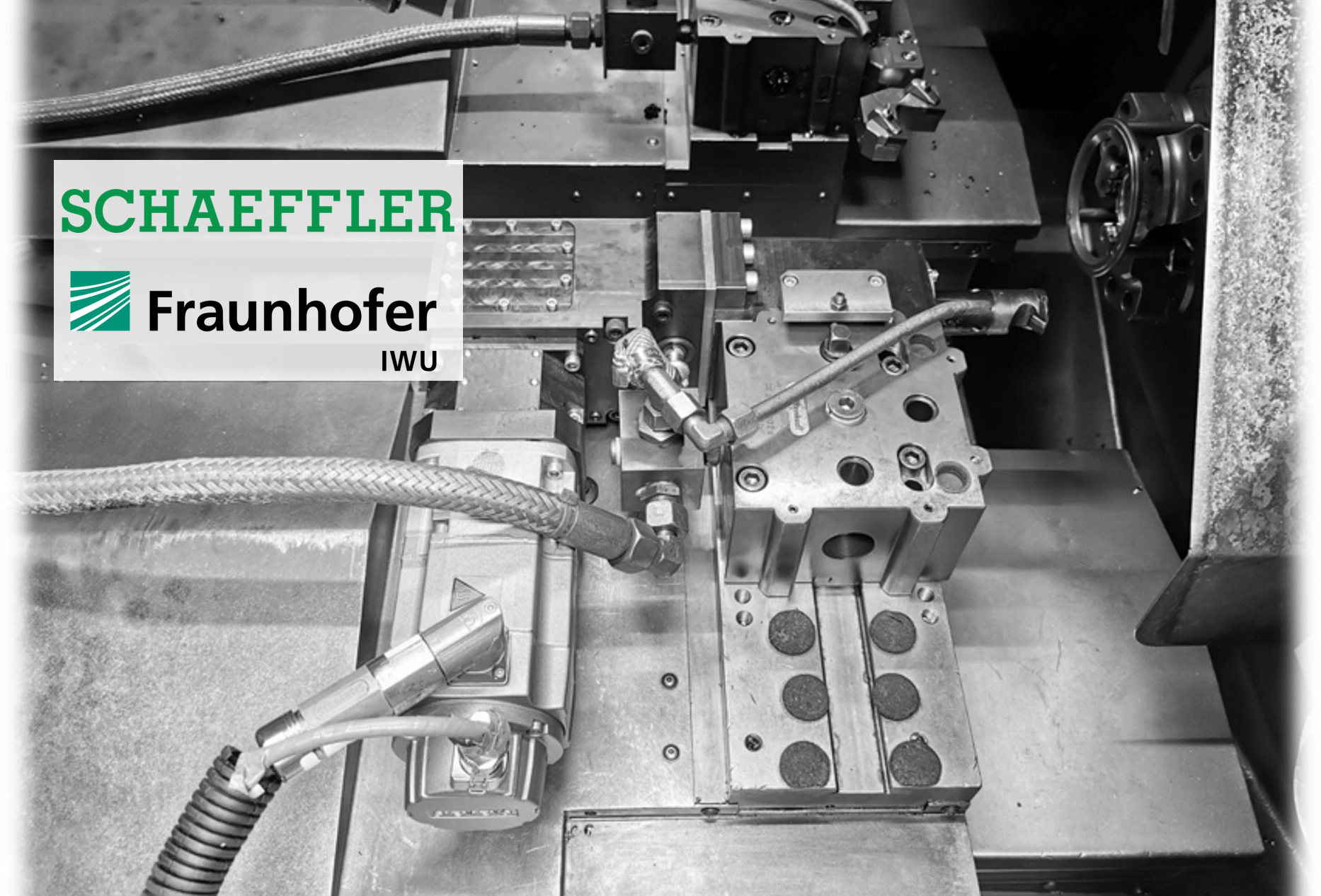

In a joint project between Schaeffler AG and the Fraunhofer IWU, an oscillation system with its own drive was developed and successfully integrated into a machine tool for machining wheel bearings. The innovative technology enables a defined oscillation movement in the feed direction during the turning process. As a result, weak points in the chip can be generated in a targeted manner to ensure optimum chip breaking.

Download now