info@vibrocut.de

info@vibrocut.de

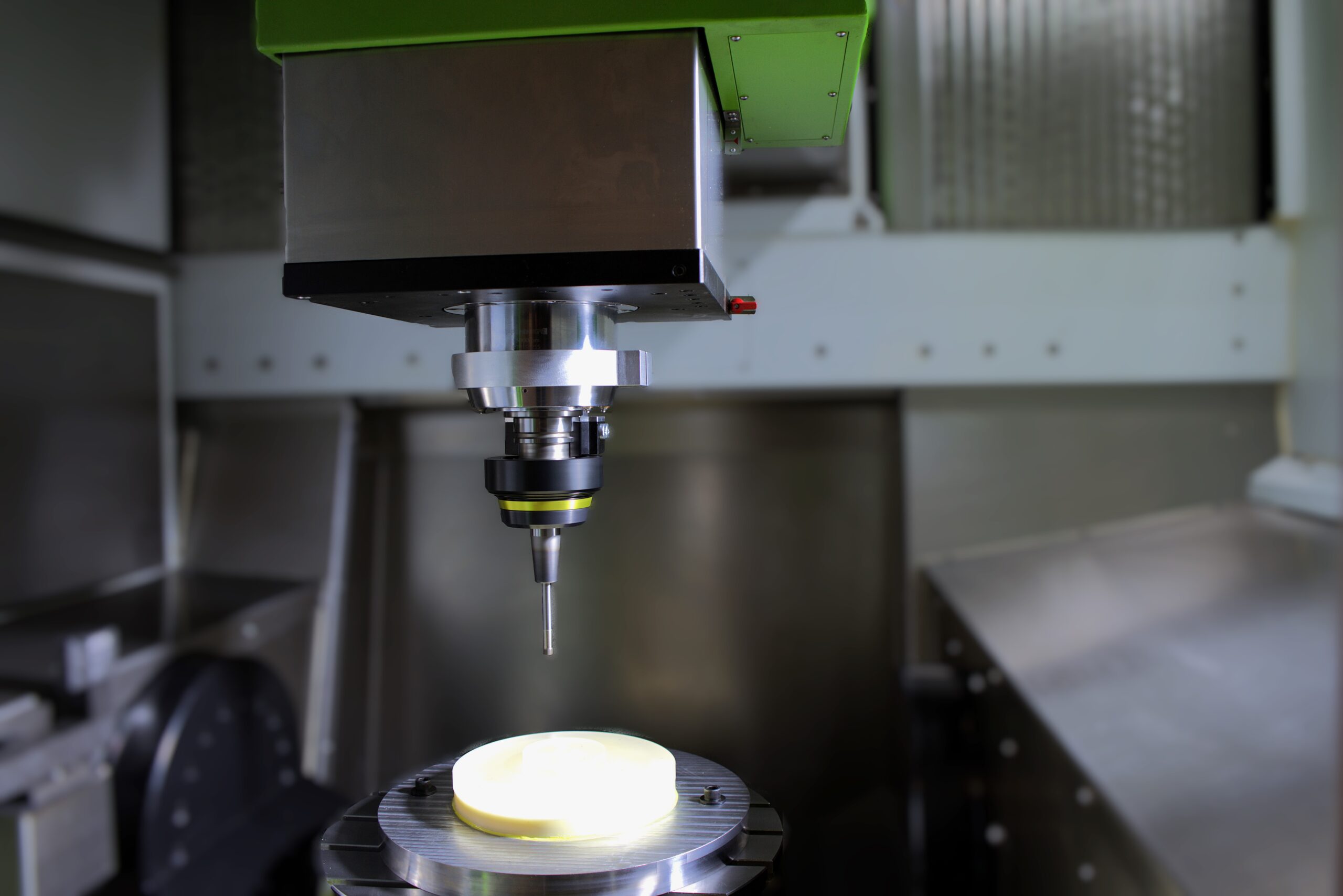

Our VibroCut ultrasonic tool holders optimize grinding processes by using the latest ultrasonic technology. The high-frequency additional movements specifically improve material removal, reduce process forces and minimize microcracks – a decisive advantage when grinding brittle-hard materials such as glass or ceramics.

Use the versatile possibilities of VibroCut ultrasonic to make your grinding processes more precise, safer and more efficient. Raise productivity and quality to a new level!

Quartz glass and technical ceramics such as aluminum oxide are key materials in high-tech sectors such as the semiconductor industry, optics and medical technology. However, their high hardness and brittleness pose particular challenges for machining, as they can lead to microcracks, increased tool wear and limited surface quality.

Ultrasonic assistance in the grinding processes offers decisive advantages here. The high-frequency movements reduce process forces, improve surface quality and minimize tool wear. With VibroCut ultrasonic even demanding geometries can be machined precisely and the efficiency of grinding processes for quartz glass and aluminum oxide can be significantly increased.

You can download the entire white paper here:

Ultrasonic-assisted grinding of quartz glass and aluminum oxide with VibroCut ultrasonic