info@vibrocut.de

info@vibrocut.de

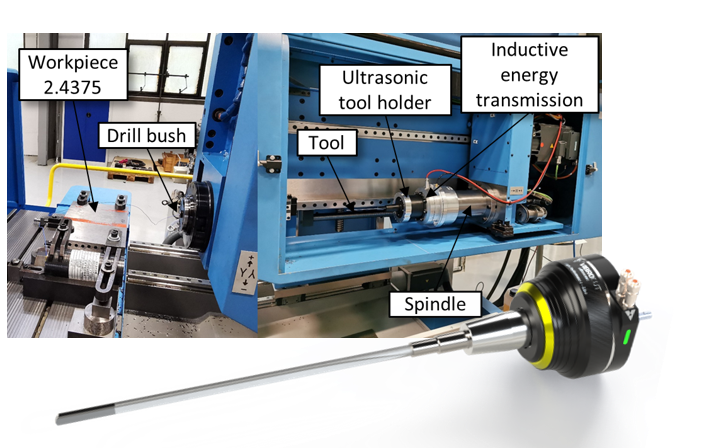

Our VibroCut ultrasonic tool holders optimize the cutting process by using the latest ultrasonic technology. High-frequency additional movements significantly reduce machining forces and friction – a decisive advantage, especially when drilling and deep hole drilling.

Use the versatile application possibilities of VibroCut ultrasonic to make your production processes more efficient and more powerful. Unlock new potential and take your machining to the next level!

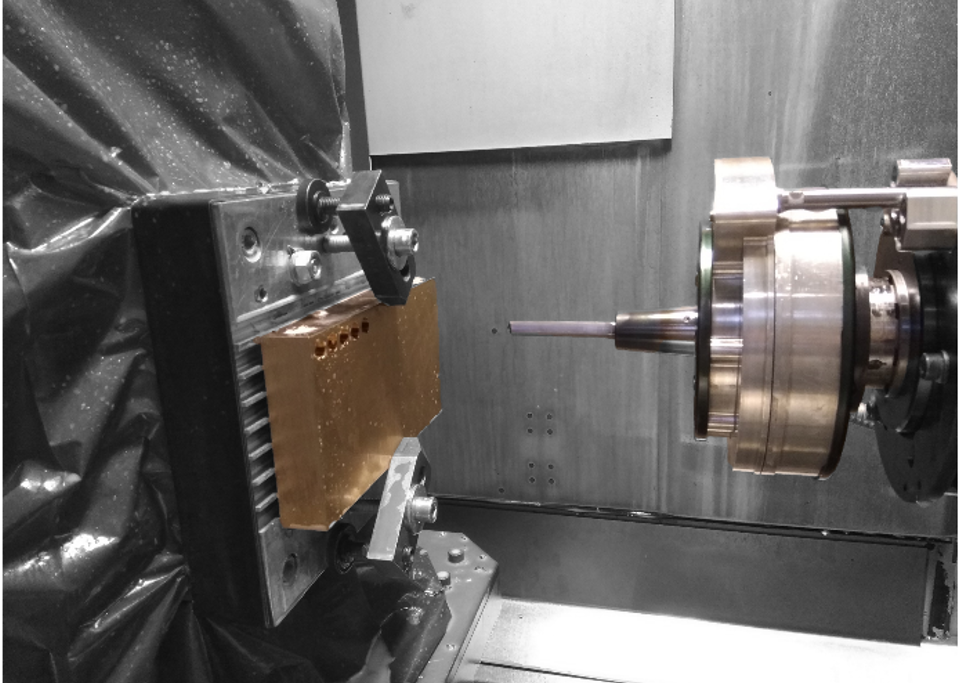

Components made of copper and copper alloys can be found in essential components in various sectors such as the electrical industry or energy technology. In many cases, they are manufactured using machining processes, whereby various processes such as drilling and deep hole drilling are used. Despite their comparatively low strength, copper-based materials and low-alloy copper alloys in particular are considered difficult to machine. The reason for this is the tough material behavior with high formability. This results in poor chip formation behavior and high machining forces, which pose a challenge for industrial processes in terms of productivity, process reliability and quality. Find out how VibroCut ultrasonic helps to overcome these challenges.

You can download the entire whitepaper here:

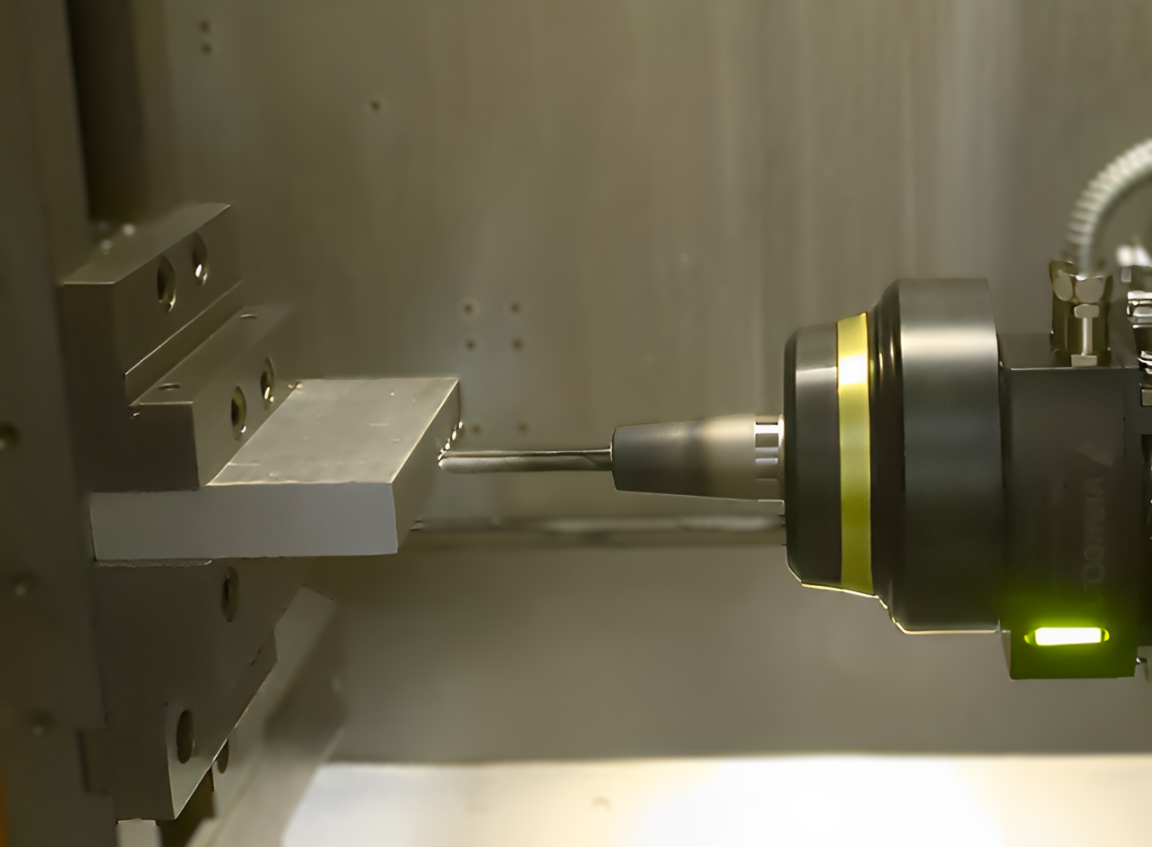

Components made of aluminum alloys are used as wrought or die cast alloys in almost all industries. Due to their favorable material properties, low costs and good machinability, aluminum alloys are used for components produced in large quantities and manufactured as part of series production processes. The focus here is on optimizing productivity, quality and process reliability in order to continuously increase efficiency and cost-effectiveness. Ultrasonic assistance for drilling and deep hole drilling processes can make a significant contribution here. The high-frequency vibrations modify the material behavior during chip formation in favor of low cutting forces and minimize friction, which significantly increases the performance of drilling and deep hole drilling processes in aluminum alloys.

You can download the entire whitepaper here:

Ultrasonic-assisted drilling and deep hole drilling of aluminium alloys with VibroCut ultrasonic

Nickel-based alloys such as Monel K500 are characterized by high strength and heat resistance – but are difficult to machine. High machining forces, insufficient chip removal and heavy tool wear lead to process-related challenges, especially in deep hole drilling.

VibroCut ultrasonic improves these processes through targeted ultrasonic movement of the tool: cutting forces are reduced, chip transport is facilitated and wear is minimized.

You can download the entire whitepaper here:

Ultrasonic-assisted deep hole drilling of nickel-based alloys with VibroCut ultrasonic