info@vibrocut.de

info@vibrocut.de

Friction Stir Welding (FSW) is an innovative process for joining lightweight metals, especially aluminum. It is characterized by high seam quality, minimal distortion, and the ability to process a wide range of materials. Industries such as aerospace, automotive, and rail vehicle manufacturing benefit from the outstanding properties of the joints and the flexibility of the process.

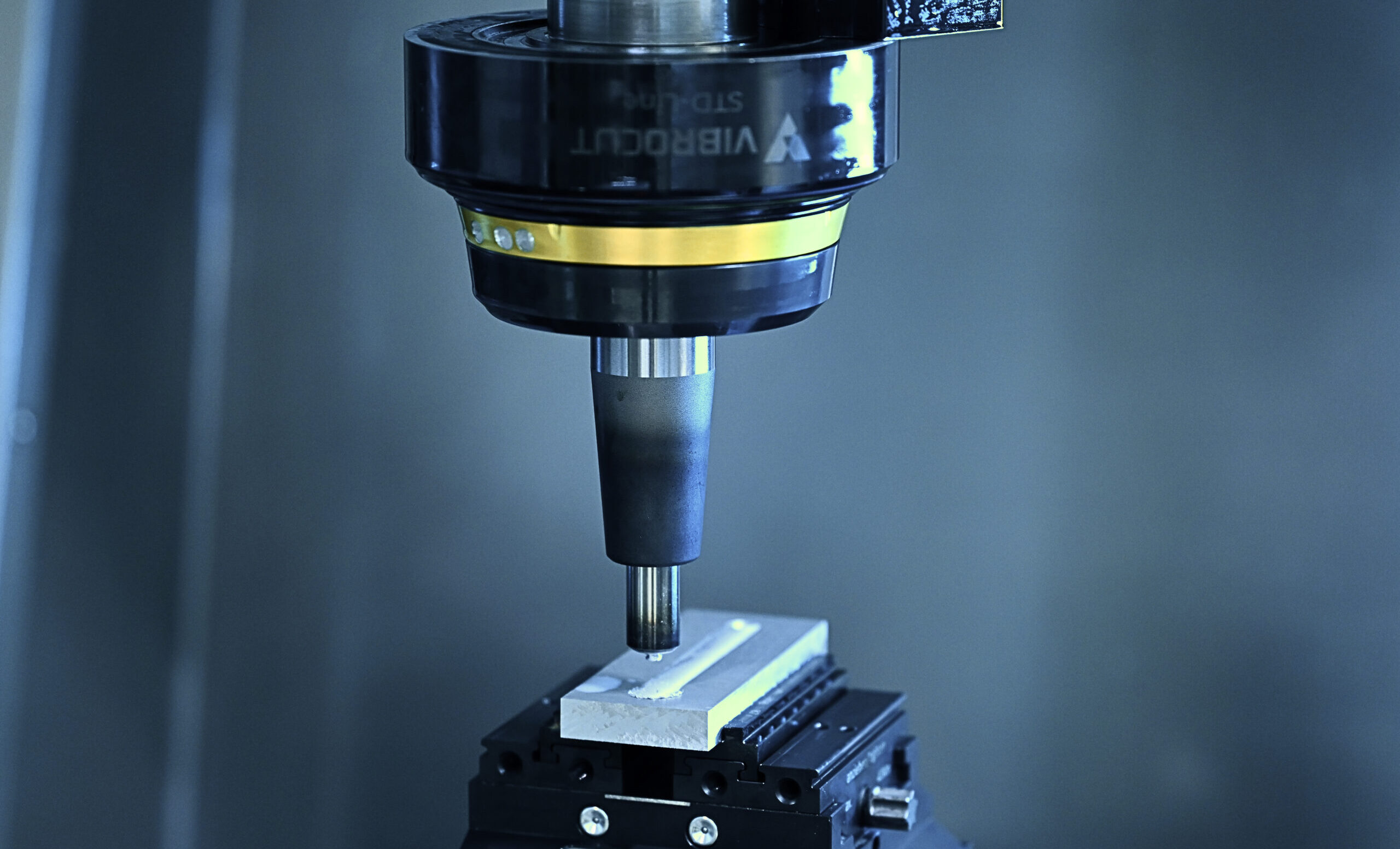

The VibroCut ultrasonic tool holders induce a precise ultrasonic motion into the welding tool. This directly introduces additional energy into the joining zone, supporting material plasticization and mixing.

The ultrasonic motion significantly reduces welding forces and improves mixing in the joint zone. Oxide lines and brittle intermetallic phases are minimized, enhancing seam quality in terms of tensile strength and elongation at break. An integrated sensor system measures the ultrasonic properties and enables high-dynamic control, ensuring constant process parameters — even for large components or demanding alloys.

VibroCut ultrasonic addresses key challenges in friction stir welding:

|

These effects significantly increase process reliability while simultaneously enhancing productivity.

With VibroCut ultrasonic, users gain significant advantages in the friction stir welding process:

Improved mechanical properties of weld seams

Higher efficiency and cost-effectiveness of the overall process

Applicable in both new systems and retrofitted machines

Reproducible results for demanding components and alloys

VibroCut ultrasonic combines innovative technology with precise control to ensure maximum process stability and the highest seam quality.