info@vibrocut.de

info@vibrocut.de

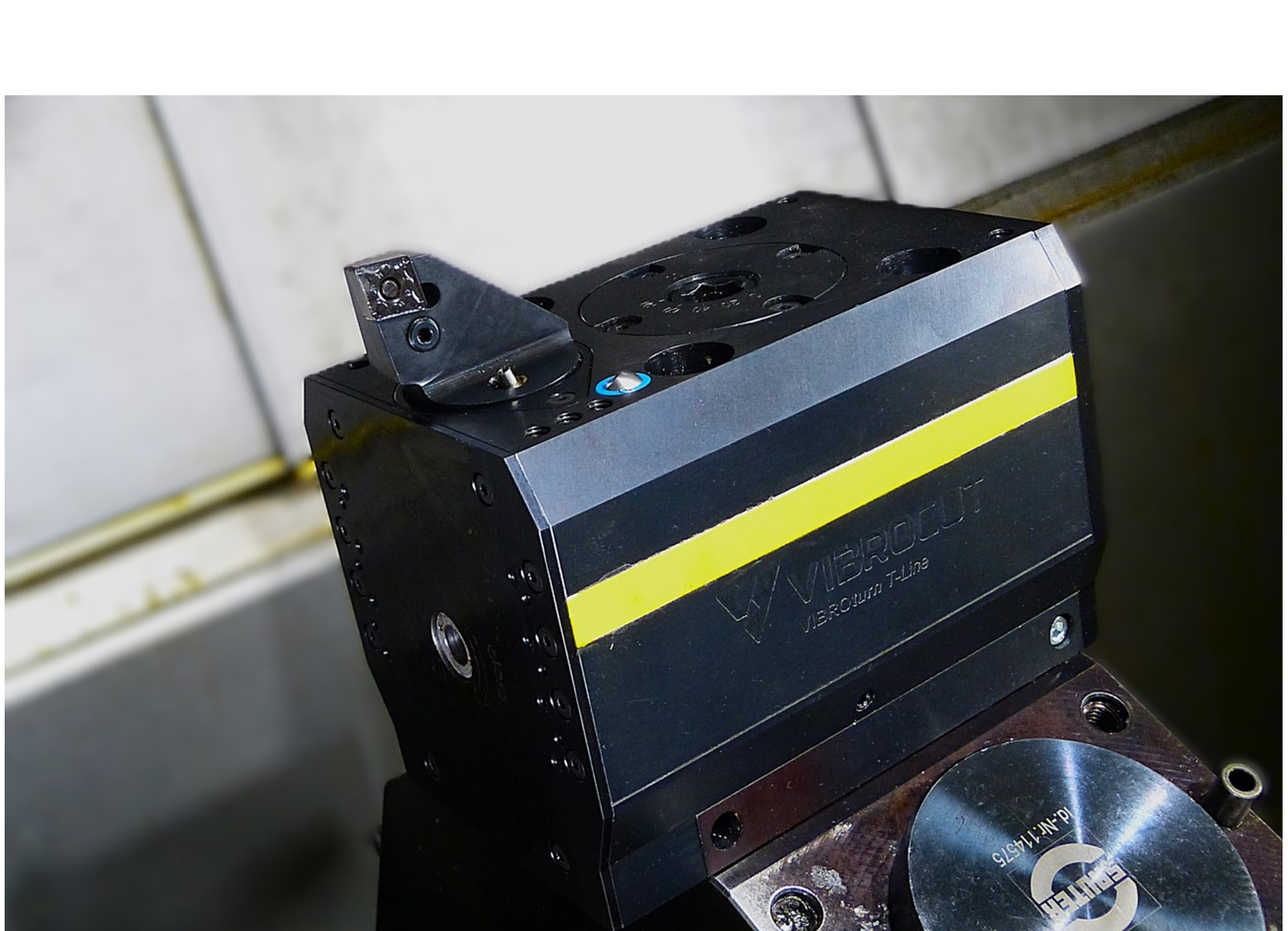

Turning is of great importance as the primary process for manufacturing rotationally symmetrical components. With VIBROturn, chip breaking is improved during turning, thereby increasing productivity and process reliability.

In turning, the chip breaking problem has not yet been solved in a reliable way. The reasons for this lie in the continuous cutting engagement. Insufficient chip breaking can cause a variety of problems:

VIBROturn generates a defined oscillation of the tool, introducing predetermined breaking points to enable a process-secure chip breaking. Where previously turning machines had to be stopped several times an hour for manual chip removal, even in series production, chip breaking now no longer causes interruptions of production. By avoiding downtimes, productivity is significantly increased.

Process uncertainties caused by chips, such as scratched surfaces, clamping errors, tool breakages, etc., are prevented by the short broken chips. VIBROturn uses tools for external and internal machining. This supports processes such like longitudinal turning, face grooving, parting off up to centric drilling with a low-frequency vibration.

By using VIBROturn you will receive the following added values:

|

Increase in productivity |

|

Increase in process reliability |

|

Cycle time neutral vibration assistance |

|

Equipment of existing machines |

The following calculation shows, as an example for a turning process, the potential savings for an equipped machine if machine downtimes caused by chip breakage are avoided.

|

Machine hour rate: 85 €/h |

|

Planned occupancy time: 6000 h/year

750 shifts/year |

|

Chip breakage caused machine downtime:

2 – 6 min/h |

Downtime due to chip breakage

2 min/h

4 min/h

6 min/h

Usage loss per year

200 h (3.3 %)

400 h (6.7 %)

600 h (10 %)

Downtime costs per machine

17,000 €

34,000 €

51,000 €